The world class Expert in the circular economy of urban mines

Zero Hazardous Waste Recycling

As a leading player in the refining of precious metals, the processing and recycling of spent precious metal catalysts is one of our core competencies. We receive spent catalysts from the fine chemical, pharmaceutical, and agrochemical industries in order to refine and recover the customer’s precious metals, maximizing their profitability in a totally transparent process.

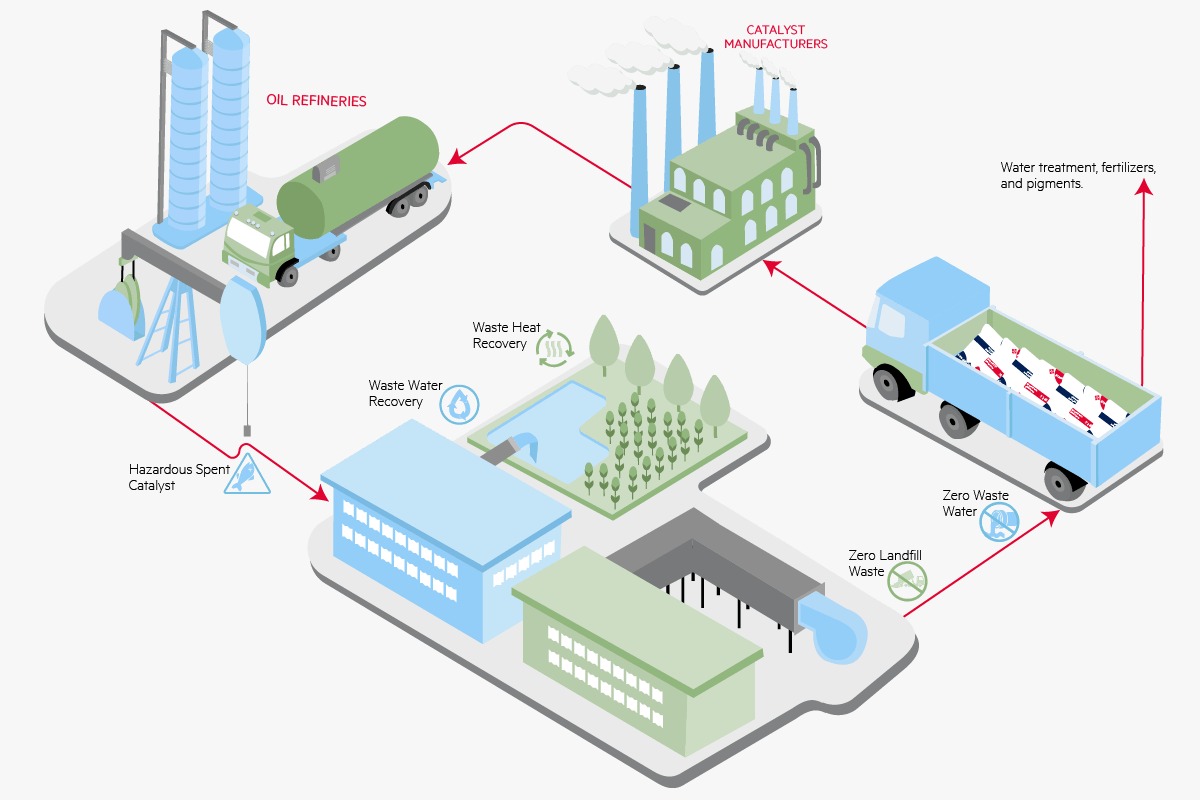

HIGH CIRCULARITY - CRADLE TO CRADLE

We help refineries and catalyst manufacturers eliminate the end-of-life impact of products and processes by recovering every element in the spent catalyst. The metal compounds can then be distributed back to catalyst manufacturers for re-use in manufacturing, thereby bringing hazardous waste back to the cradle. In India we have been recognized as a circular recycling company, we have been able to contribute majorly to protecting the environment.

Process

Some of the processes at RandRock include Roasting, Leaching, Purification, Precipitation, Drying and Calcination. Our unit has excellent capabilities for all these processes.

Our Products:

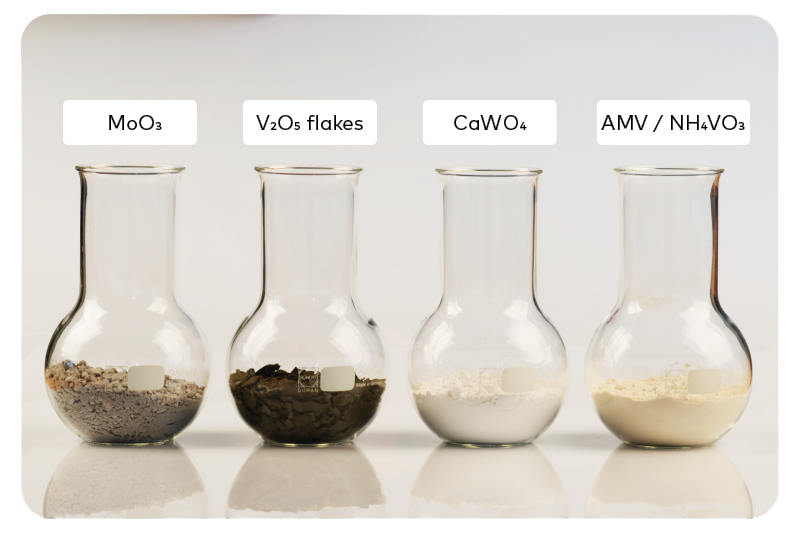

RandRock converts hazardous spent catalyst into high purity metal compounds and value added chemicals that can be used again in the process of catalyst manufacturing.

Industrial Catalyst Products

- Molybdenum Trioxide - MoO3

- Vanadium Pentoxide Flakes - V2O5

- Calcium Tungsten Oxide - CaWO4

- Ammonium metavanadate - AMV/NH4VO3

- Cobalt Sulphate – CoSo4

- Sodium Sulphate. – Na2So4

Automotive Catalyst Products:

Platinum

Palladium

Rhodium

Applications:

Alloys

Industrial Coatings & Paints

Pigments

Catalyst

Fertilizers

Lab Reagent

Molybdenum Powder